Having worked with thousands of excavator operators and owners around New Zealand every year, operating in a vast range of applications and material types, day after day we get to see the effects abrasive materials have on the cutting edges of Tilt and Wide buckets.

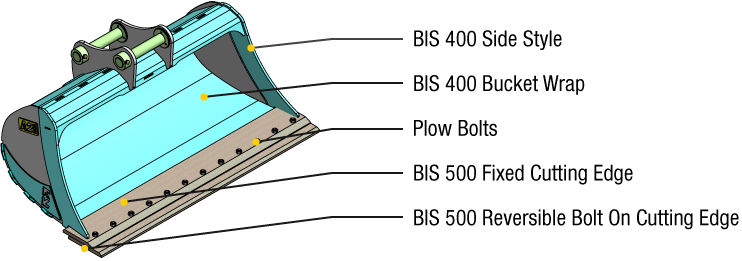

In this short article, we discuss the reasons why we supply all our Wide & Tilt Buckets from the 5-tonne range and up as standard with a double-sided BIS500 Bolt on Cutting Edges (fitted underneath the existing BIS500 Fixed Cutting Edge).

1. No need to cut it off or use a welder when the cutting edge is worn out

With a Bolt on Cutting edge, gone are the days of cutting off the fixed Cutting Edge and welding in a new one (half a day's work)! By simply removing the Plow-Bolts turning the Bolt on Cutting Edge around to the new edge (or replacing it if fully worn out) and re-applying the Plow-Bolts, you will back working within the hour.

2. Twice the lifetime before needing replacement

Our Bolt on Cutting Edges are double-sided and extra heavy-duty BIS500 grade steel; this means that in the time you have worn out both sides someone without a Bolt on Cutting Edge would have needed to cut off their fixed edge and replace it twice (taking a lot of extra time and resources).

3. Extra bucket capacity

When fitted with a Bolt on Cutting Edge, the capacity of your Tilt or Wide Bucket is increased due to the additional floor length created by the Bolt on Cutting Edge sticking out the front of the fixed cutting edge. On a 12 tonne wide Bucket, the floor-length is increased by 75mm giving it 14.7% more capacity.

4. Less wear on side styles and bucket wrap

With the Bolt on Cutting Edge extending the floor out further you won't suffer as much wear at the bottom of the side styles, without a Bolt on Cutting edge you will begin to wear into these before replacing the fixed cutting edge – requiring extra engineering work when you replace the fixed cutting edge.

Also with the extra thickness created by the Bolt on Cutting edge, it lifts the entire base of the bucket off the ground slightly – this means while digging or grading the floor of the bucket is less likely to come in contact with the ground decreasing drag and wear.

5. More rigid cutting edge meaning no need for a rib

With a Bolt on Cutting Edge, you have double the thickness creating a more rigid front to the bucket, this combined with our BIS400 bucket wraps and wear strips, these make for a very stiff and durable bucket. This means there is no requirement for a rib – saving material clogging up around it.

There you have it – five reasons why you should run a Bolt on Cutting Edge on your Wide or Tilt Buckets. Here at Attach2, we provide all our wide and Tilt Buckets from 5 tonnes and up as standard with a heavy-duty BIS500 Bolt on Cutting Edge as well as the fixed BIS500 Cutting Edge.